Tamper-Proof Laser Marking for Battery & Energy Manufacturing

Target Audience: Production and Quality Managers in Gigafactories for Li-ion cells, modules, and stationary energy systems.

Executive Summary

Implementing tamper-proof laser marking on cell and module housings unlocks three powerful value drivers in battery factories—with measurable results:

Regulatory Compliance & Future-Readiness

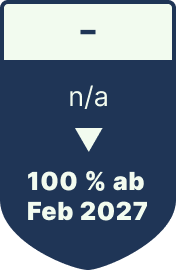

Starting February 2027, the EU Battery Regulation requires a digital battery passport with a persistent product identifier throughout the lifecycle. A directly engraved laser ID meets this traceability requirement without adhesive labels, avoiding retrofit costs, production stops, or regulatory fines.Scrap Reduction & OPEX Efficiency

According to a Fraunhofer whitepaper, full traceability can reduce cell production scrap rates by up to 10.3 percentage points. In a 40 GWh gigafactory, that translates—conservatively—to over €100M in annual savings. The laser ID ensures seamless traceability from the very first production step.Recall Risk Mitigation

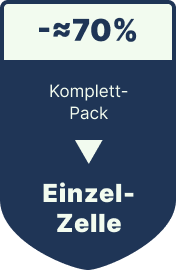

The GM Bolt recall is a cautionary tale: missing cell-level traceability led to ≈ $2B in losses. Precise, serialized laser marking reduces replacement volumes to truly affected batches, cutting recall costs by 70% or more.

Together, these levers yield a payback period of well under 12 months and generate a double-digit million net present value (NPV) within five years—while delivering full compliance and brand protection from counterfeits.

Challenges

| Driver | Risk Without Tamper-Proof Laser ID |

|---|---|

| EU Battery Regulation: From Jan 1, 2026, all traction and industrial batteries >2 kWh must feature a digital passport with a permanent QR/Datamatrix code. | Post-labeling causes downtime, integration rework, and non-compliance penalties. |

| High Ramp-Up Scrap Rates: 15–30% scrap is typical in early production. | Every additional % scrap = up to €30,000/day. Break-even at risk. |

| Multi-Billion Recalls: The GM Bolt recall cost ≈ $2B. | Lack of cell-level ID inflates recall volumes exponentially. |

| Counterfeits & Non-Compliant Cells: Fake batteries fuel safety risks and brand damage. | Recalls average >$1.8B per major event. |

Solution Approach

- Laser Engraving of DataMatrix or QR Codes

Applied directly to aluminum or steel cell housings—durable, tamper-proof, and permanent. - No Consumables Required

No labels. No inks. No changeover materials. - Battery-Passport-Ready Architecture

Serial number links to process and quality data in real time. Seamless integration into MES and compliance platforms.

Note: Focus on tamper resistance and data integrity. No thermal or chemical durability claims.

Real-World Application Areas

| Process Step | Technical Integration | Direct Value |

|---|---|---|

| Cell Production (post-sealing) | Inline laser station + vision system; code engraved in <0.3 s and OCR-verified; data flows to MES/passport backend | Unique cell ID from unit #1; enables early scrap detection and full genealogy |

| Module/Pack Assembly | Laser-ID scan married to BMS serial, cooling plate, etc.; mapping via API to traceability layer | Eliminates cell mix-ups; automates release tests; secures module/pack genealogy |

| Second-Life Sorting | Stationary scan pulls SoH & cycle history; algorithm assigns A/B/C grades | Enables automated reuse decisions; lowers testing costs |

| Recycling/Dismantling | Vision-guided robot reads IDs for precise material stream separation; volumes auto-logged | Faster dismantling; up to +12% raw material recovery; full battery passport compliance |

Business Value & ROI

| Cash Flow Item | Year 0 (CapEx) | Year 1 | Year 2 | Year 3 | Total (3 Y) |

|---|---|---|---|---|---|

| 20 Laser Stations (€250k each) | -€5.0M | – | – | – | -€5.0M |

| Integration & Training | -€1.0M | – | – | – | -€1.0M |

| Maintenance (€0.2M/year) | – | -€0.2M | -€0.2M | -€0.2M | -€0.6M |

| Scrap Savings (-5 PP = €50M/year*) | – | +€50M | +€50M | +€50M | +€150M |

| Recall Risk Reduction (≈ -70% = €4M/year) | – | +€4M | +€4M | +€4M | +€12M |

| Net Cash Flow | -€6.0M | +€53.8M | +€53.8M | +€53.8M | +€155.4M |

*1 PP scrap ≈ €10M/year in 40 GWh plant. Even half the Fraunhofer potential (5 PP) = €50M/year savings.

Payback Period: < 2 months, ROI (3 Y): ≈ 25:1

Implementation Roadmap

| Phase | Duration | Key Stakeholders | Estimated Effort |

|---|---|---|---|

| 1. Analysis & Specs – Process audit, code layout, MES interface | 4 weeks | Production, Quality, IT, Procurement | 8 person-days |

| 2. Pilot Line (PoC) – 1 laser station, OEE tracking | 6 weeks | Production Mgmt, Equipment Vendor | 120h setup + 40h training |

| 3. Scale-Up (Cell & Module Lines) – 20 stations incl. buffers | 12 weeks | PMO, Automation, Maintenance | 6 FTEs over 3 months |

| 4. MES/Passport Integration – Code mapping, API testing | 8 weeks | IT Architecture, Quality Ops | 2 FTEs, 160 dev hours |

| 5. Global Rollout & Training – SOPs, factory standards | 6 weeks | HR Training, Lean Office | 1 FTE trainer + e-learning |

| 6. Continuous Improvement – KPI reviews, scanner fine-tuning | Ongoing | Production, Quality, IT | Monthly: 2 PT |

Key Metrics

Scrap Rate

Scrap Costs (40 GWh)

Traceability Coverage

Root Cause Time

Recall Volume

Passport Compliance

(Key Performance Indicator, delta, baseline, result)

Explanatory Notes

- Scrap Reduction Potential:

A study by Fraunhofer FFB quantifies up to –10.3 percentage points reduction in scrap rates through full traceability. In a 40 GWh factory, each percentage point equates to ~€10 million in annual savings. - Recall Mitigation:

The GM Bolt case illustrated the massive financial impact of insufficient traceability, leading to ~$2 billion in recall costs. Secure laser marking can reduce affected volumes by ≈70%, significantly lowering financial exposure. - Regulatory Compliance:

As of February 1, 2027, the EU Battery Regulation mandates a digital battery passport for all traction and industrial batteries >2 kWh, including a durable, scannable identifier readable throughout the product lifecycle.