Digitization through

identification solutions

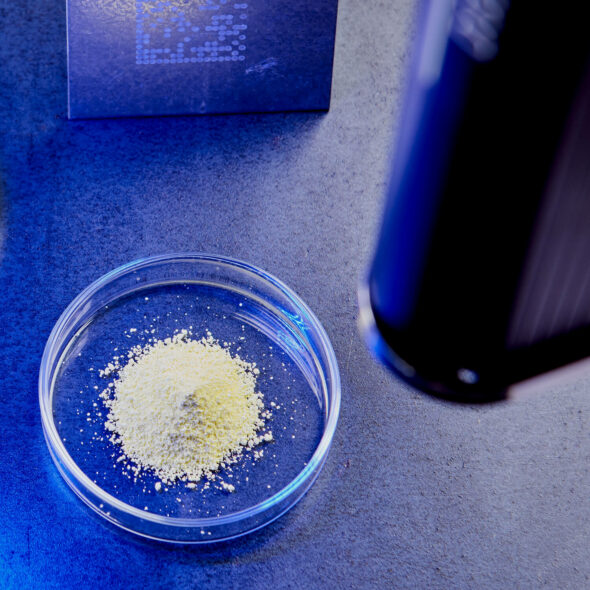

Identification

Creation of an individual digital fingerprint, even under extreme production conditions.

Information

Automated allocation of all information for reliable tracing of each component.

Insights

Linking all relevant information - for more efficiency, transparency and competitiveness.

Applications

With individual answers to your challenges, we enable the identification and traceability of materials and products in the value chain. Together, we drive the digitalisation of your industry.

Learn more

Technology

Our services include new marking methods, optical identification solutions and digital networking technologies. We offer a one-stop solution for responding to complex customer requests, which includes engineering, integration and service.

Learn more

Solutions

Innovative labelling solutions and intelligent data processing are the foundation of a resilient supply chain. Let's tackle your current and future tracking and tracing challenges together.

Learn moreOur partner