Part marking for ceramic products

Challenge

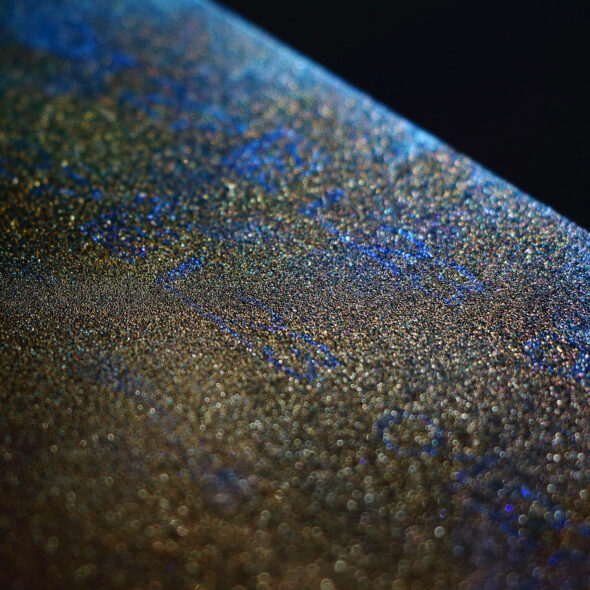

Ceramic components and ceramic kiln furniture are heat-resistant, insulating, durable and chemically stable. These high-performance materials are therefore also used in safety-critical areas or are used for their production. This makes it all the more important for manufacturers to ensure their functionality under demanding conditions and to be able to make a transparent assessment of their service life. Component-specific labelling enables manufacturers to allocate material batches and process parameters, among other things, and therefore provides extensive options for monitoring functionality, service life and quality. The information obtained is also used to precisely analyse faults and assign faults to individual components, improve processes and comply with sustainability criteria.

Consequences of a missing marking can be among others:

- Missing allocation of material batches to the individual component

- Defect analysis and process improvements are made more difficult

- Poorer evaluation in sustainability criteria due to lack of coverage of the supply chain

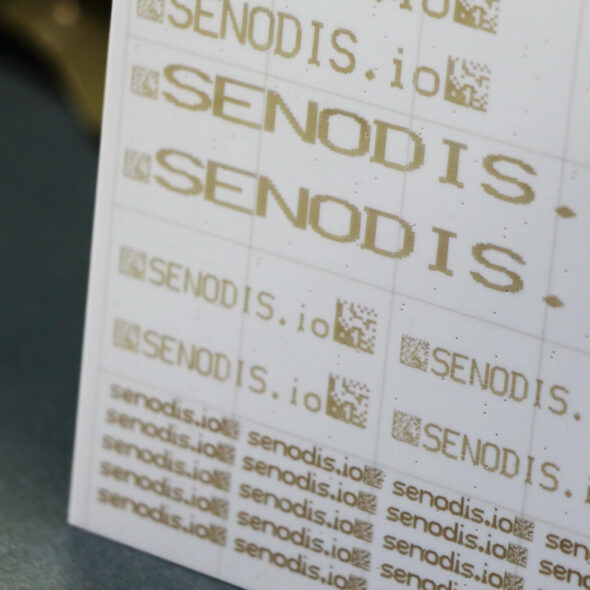

Senodis sets new standards in the handling of these tasks by consistently linking technical solution approaches and direct customer benefits.

Use case: Kiln furniture

Kiln furniture holds components in the manufacturing process and transports them safely. In monitoring, not only their respective service life is of interest, but also information resulting from the linking of kiln furniture, component and process parameters. Our applications ensure the safe connection of the components as well as the recording of the service lives.

- Linking product and process

- Most accurate determination of the service life

Use case: functional ceramic products

It is not only the supply chain law that demands the greatest possible traceability of individual parts and components. Also in terms of their own quality standards, companies strive to link products, processes and information and to enable transparency in the value chain. We support you with component-specific labelling solutions.

- Traceability

- Precise assignment of individual components to specific process steps and/or products