Markings for 3D metrology

Challenge

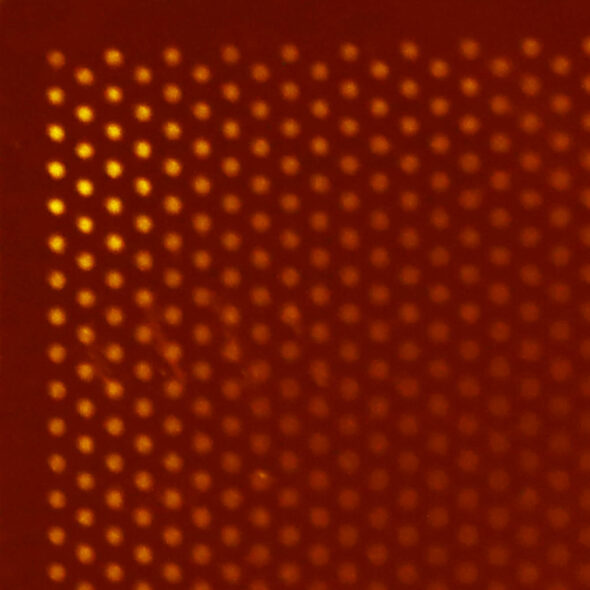

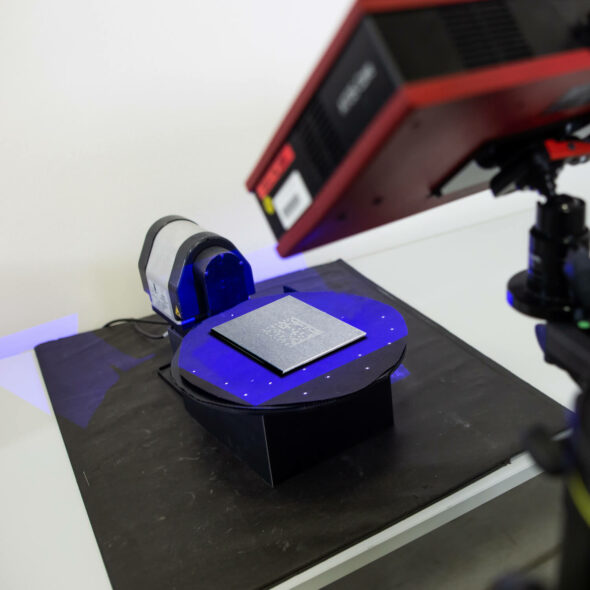

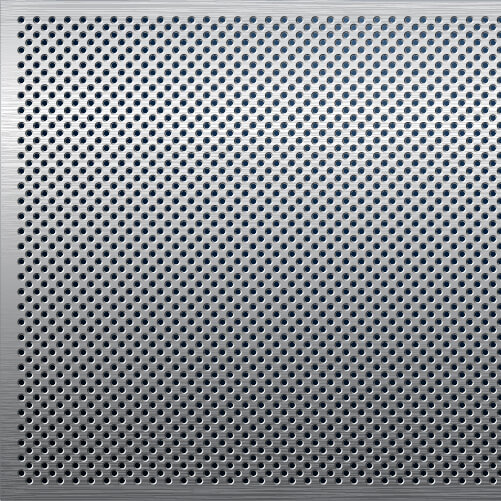

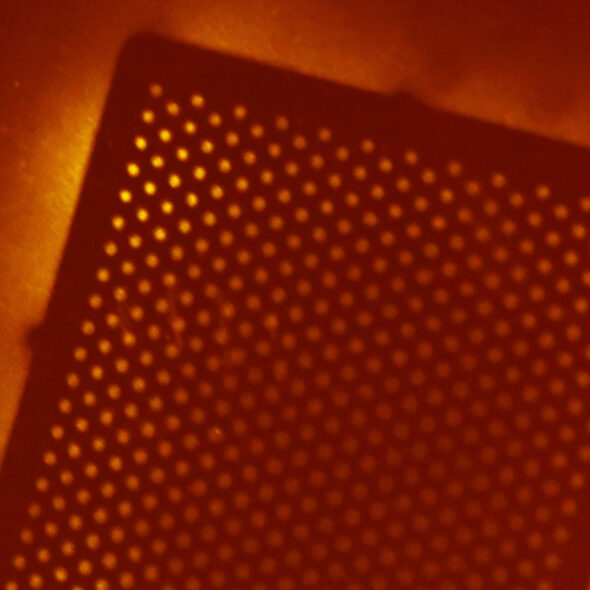

Precise marking of the components is required to accurately assess the forming results, for example in press hardening. For this purpose, a hexagonal grid pattern is usually applied to the objects using lasers and then recorded and analysed using intelligent camera systems. This process is associated with high investment costs and safety precautions.

Our technologies offer a more cost-effective and simpler alternative: with CeraCode® ink, patterns can be applied to the components before the forming process using airbrush systems or inkjet printing, for example. In the subsequent high-temperature and forming step, the marking bonds permanently with the component, allowing targeted analyses of forming degrees and simulations in sheet metal forming.

The advantages of Senodis technologies are:

- Low investment costs

- No additional safety requirements compared to lasers

- Simple and fast handling with handheld devices or automated systems

The method can be used in many areas of material and process analysis and significantly reduces the effort and costs involved in improving the quality parameters of components in the metal industry.